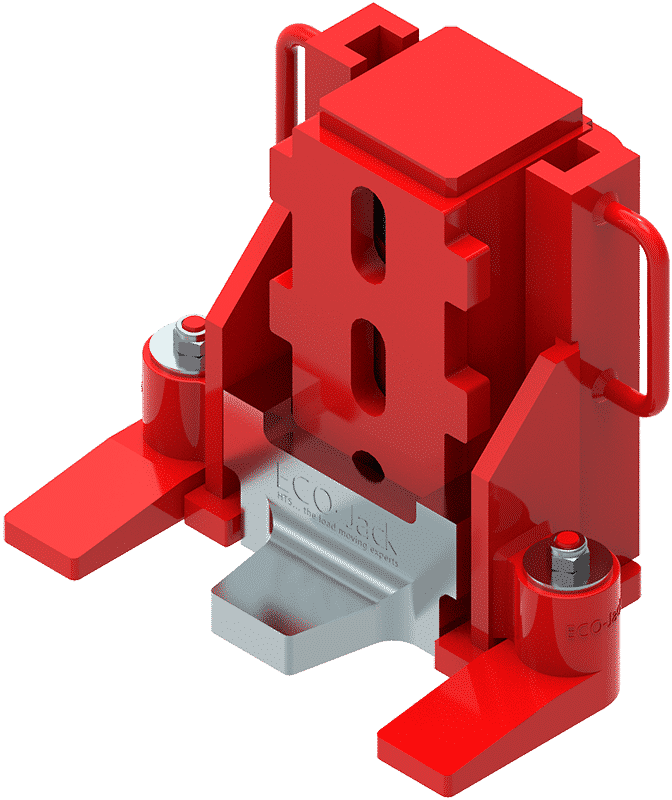

ECO-Jack® Hydraulic jacks and pumps

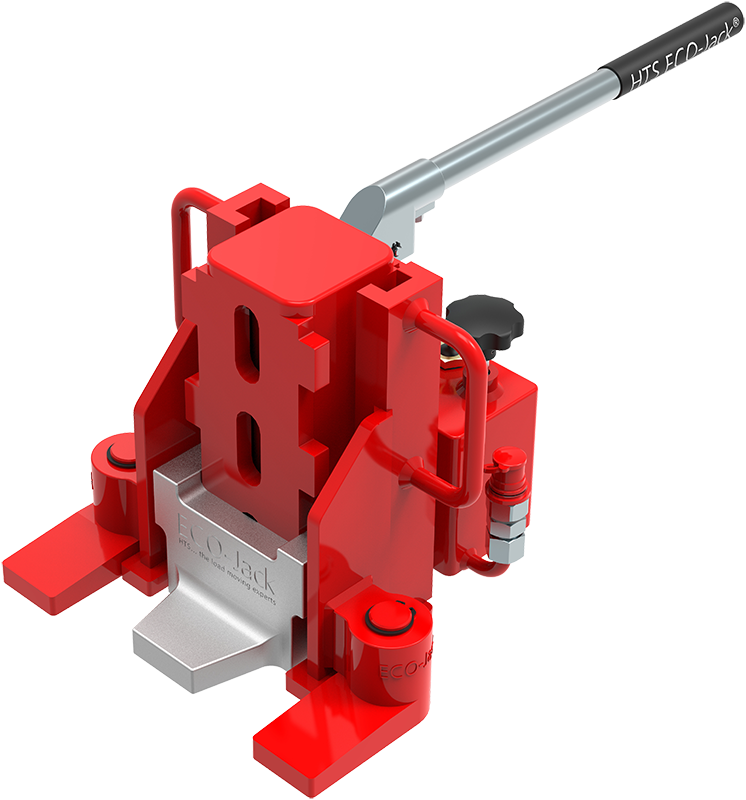

ECO-Jack®, heavy duty hydraulic jacks, are available in five different series with payloads up to 50 tonnes. The user-friendly design of the patented “one-hand” lifting claw ensures safe lifting of the payload. The positional height of the lifting claw can be adjusted easily with one hand without the need to locate through awkward angles. Easy to use with a low risk of injury. The integrated pump requires no additional equipment. From the EJ100-3S, external manual or electric pumps can also be connected. For all areas of application in which the standard range is insufficient, we design special solutions that are individually tailored to the customer needs.

ECO-Jack® Universal jack

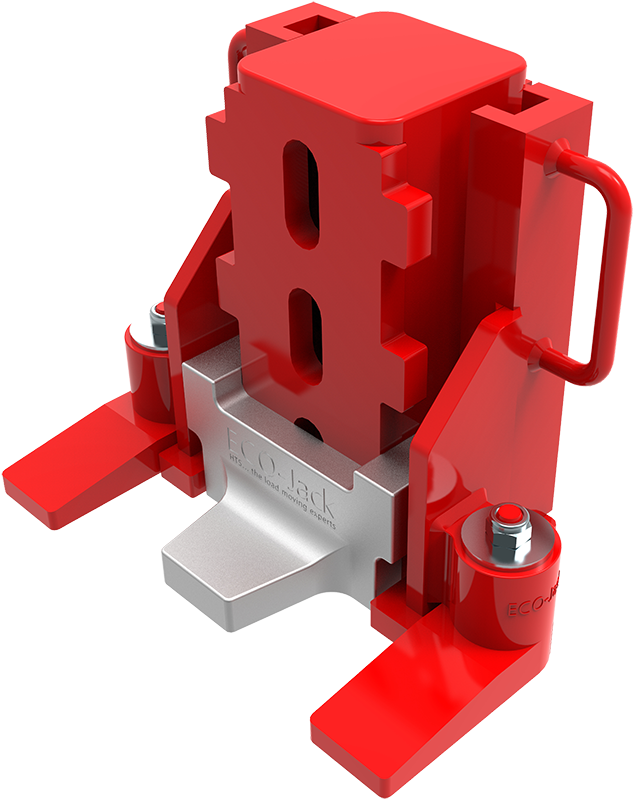

ECO-Jack heavy duty hydraulic toe jacks are available in five different series with payloads up to 50 tonnes. They are characterized by:

- the patented lifting claw. It ensures a safe lifting of heavy loads and can be adjusted with one hand without the need of tilting movement.

- a minimal self-weight. Improved construction and high-quality material have reduced weight by up to 20% compared to similar devices.

- Precision milled guides made of high resistant and high quality material that guarantee precise lifting and lowering movements and a long service life.

- a pump unit which can be swiveled by approx. 225 °. It allows the full pump stroke from any position.

- a finely dosed release valve, with which the load can be lowered precisely, and the lowering speed can be precisely controlled.

- Strong swiveling legs to secure the load to be lifted. Tilting of the machine lifter is prevented.

- An external hose coupler is standard with a load of more than 10 tonnes. External pumps can be connected with the drip-free hydraulic nipple.

For all areas of application in which the standard equipment is not sufficient, we design special solutions that are individually designed to customer needs.

Download our 2025 HTS Brochure

Download our 2025 HTS Brochure